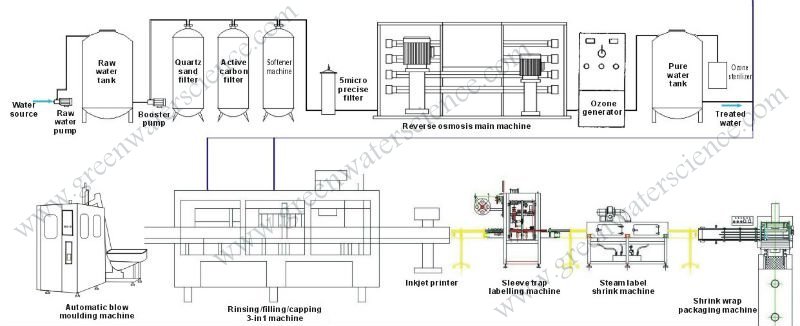

- Process I: Sediment Backwashing Pre-Filter - This filter contains high capacity and high purity media which has high dirt-carrying capacity. It filters out all sand, silt, and sediment to below 5 microns to protect the system.

- Process II: Carbon Backwashing Carbon Pre-Filter - At this point, this filter with high grade Coal,Wood,Coconut Shell Granular Activated Carbon (GAC) removes the chlorine, chemicals, pesticides and other undesirable organics.

- Process III: Twin-Alternating Water Softener - The advantage of a twin-alternating water softener is a huge advantage in that there is always soft water feeding the reverse osmosis system 24/7/365. It will increase the life of membranes and enables the system to produce high-quality water for a long period of time with minimal maintenance and expense.

- Process IV: Micron Filter - To filter particle sizes up to 5 micron.

- Process V:GWS Reverse Osmosis System - The most important system of the bottled water plant is the reverse osmosis system, it removes all the dissolved solids , micro biological impurities, chemical and all excess contaminants in the water.

- Process VI: Ultraviolet Disinfection System - To ensure Virus, bacteria and micro-organism free safe water.

- Process VII : Ozone generation system - Coronation is one of the method to convert impure water into to pure drinking water ,ozone inactivates and destroys all bacteria, virus and protozoa’s. Ozone will oxidize both organic and inorganic substances, remove unwanted taste, odor and color, and provide effective disinfection.

Advantages

- Most powerful oxidizer available

- improves flocculation of iron

- Increases the shelf life of bottled water.

- Produces safe & bacteria-free drinking water.

- Removes heavy metals & cyanides from water.

- Been used for decades

- Iron and manganese removal

- No harmful by-products

- Environmentally friendly

Purification

The first step is water purification. Water obtained from the external source is allowed to pass through the purification unit and then stored in a stainless steel tank. After purification water is taken to the bottling section. Bottling is done as a continuous operation. Purification is followed by bottle Rinsing, Filling and Capping. The unit automatically fills, rinses, and screws the cap on it. Finally mineral water is labeled, packed and marketed.

Raw Water Supply Pumb

Centrifugal pump in C.I construction is required for feeding raw water from underground/overhead raw water storage tank to PSF to ACF and then on to MCF with required flow rate of per Hour. The pump is fitted with suction/discharge pipe work, isolation valves and pressure monitor

Pressure Sand Filter

This is a FRP Pressure vessel with internal distribution, collection, frontal and interconnecting pipes and requisite valves of SS construction along with one lot of fine sand, silex and pebbles. The necessary instruments like inlet/outlet, pressure monitors and Multiport Valve for Backwash, rinse and filter provided with the system. All the suspended solids and dust particles from the raw water is removed here

Activated Carbon Filter

This is a FRP Pressure Vessel with internal distribution, collection, frontal and interconnecting pipes and requisite valves of SS construction along with one lot of fine wash high iodine content carbon flakes. The necessary instruments like inlet/outlet, pressure monitors and Multiport Valve for backwash, rinse and filter provided with the system. All the physical impurities such as odour and color of raw water is removed here

Softner Filtration

This is a vessel contains ION EXCHANGE resins. Softening is done through this ion exchange resins to remove small micro pollutants and hardness.

Micron Cartridge Filter

The Module consists of Multiple Polypropylene Cartridges with size of 10/5 Micron that prevents micron size particles up to 5 micron. Necessary instrument like inlet/outlet pressure monitor and a Flow indicator is provided with requisite isolation valves.

Chemical Dosing Pump

This is electronic chemical injection system to remove all scale formation minerals from process raw water to reverse osmosis membranes and is precautionary measure to shield the membranes from blockage of pores.

High Pressure Pump

One No. of Vertical Mounted Multi stage centrifugal High Pressure Pump with SS construction. The High Pressure Pump supply raw water with pressure as required to RO Membranes.The necessary instruments like High and Low pressure switch, pressure monitor and requisite isolation valves provided.

Reverse Osmosis System

R.O. System removes 90-95% of Total Dissolved Solids by the art of ‘Reverse Osmosis Process’. This system consist of a S.S Skid for mounting of high pressure tubes in FRP with resistance of 150 psi for pressure housing spiral wound TFC Membrane elements With necessary control valves at feed, product and reject pipe are provided with required instruments like Low and High pressure switches are provided for safe operation of High Pressure Pump under specified operating conditions. Pressure monitor is provided for pressure indication and control of complete R.O System.

Product Water Storage Tank

This is a vertical storage tank which is completely made in high quality stainless steel required for storage of the processed product water.

Leading mineral water plant in kerala. We provides mineral water treatment plant and mineral water plant services kerala. Also listed in mineral water plant manufactures in kerala

Consultancy Services

- Preparation of Project Report

- Doucumentation Regarding BIS Licence

- Water Quality Management

- Water Testing

- Total Quality Control Management

- Providing Skilled Manpower

- Maintainance of Ro Plants, Filling Machines And Pet Blow Moulding Machines

- Branding & Packaging Solutions

- AMC of Existing Units